No products in the cart.

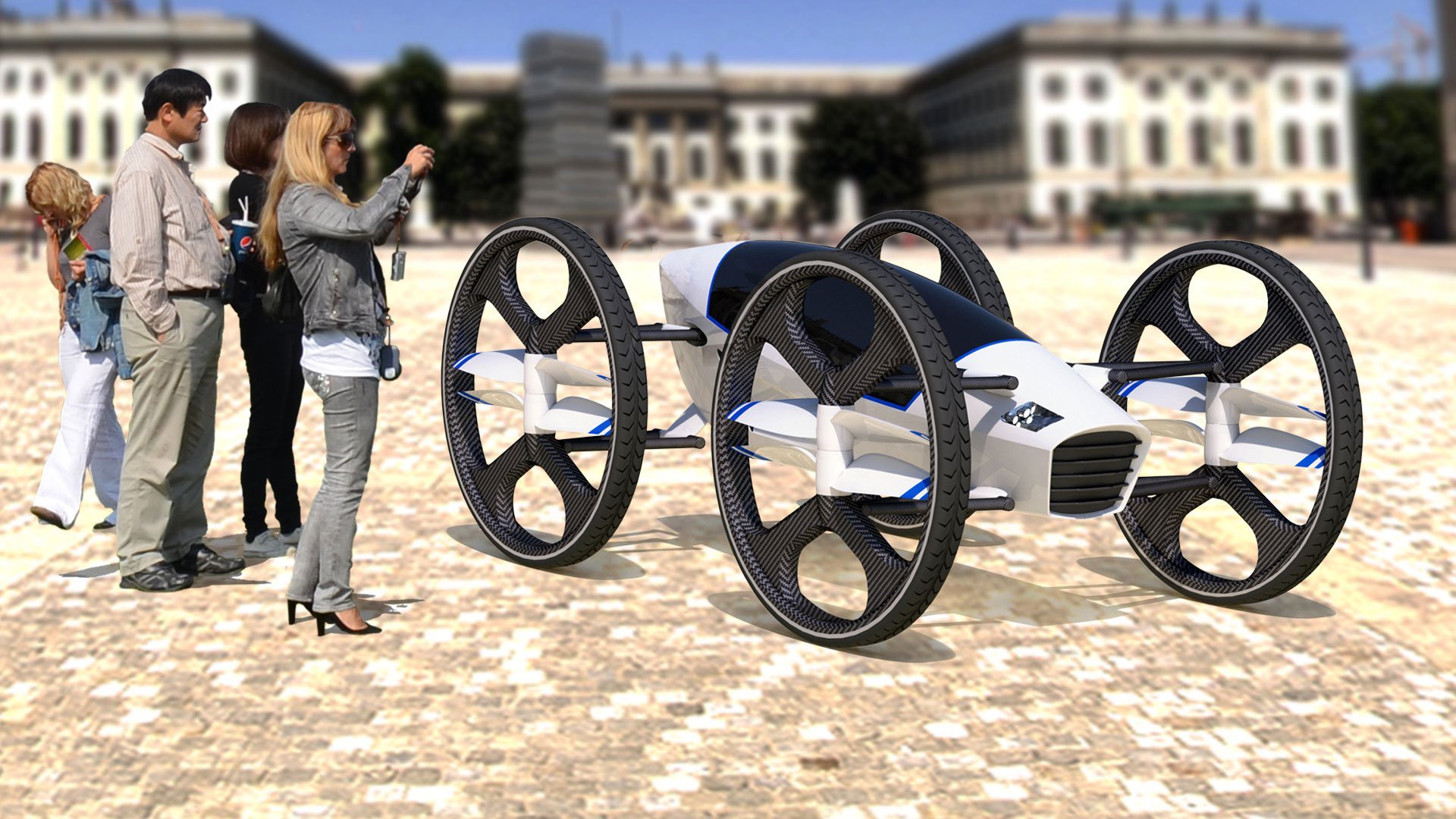

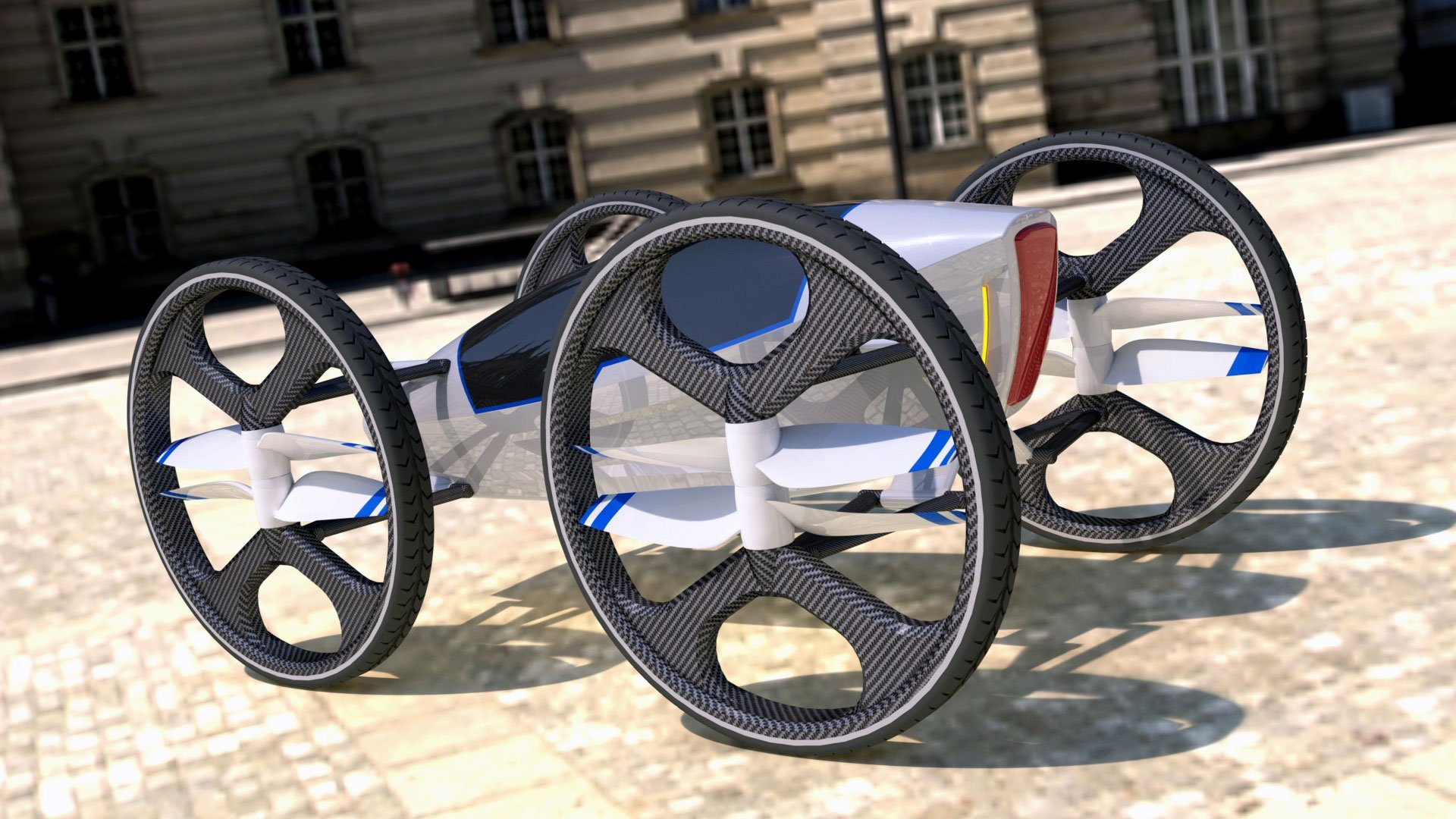

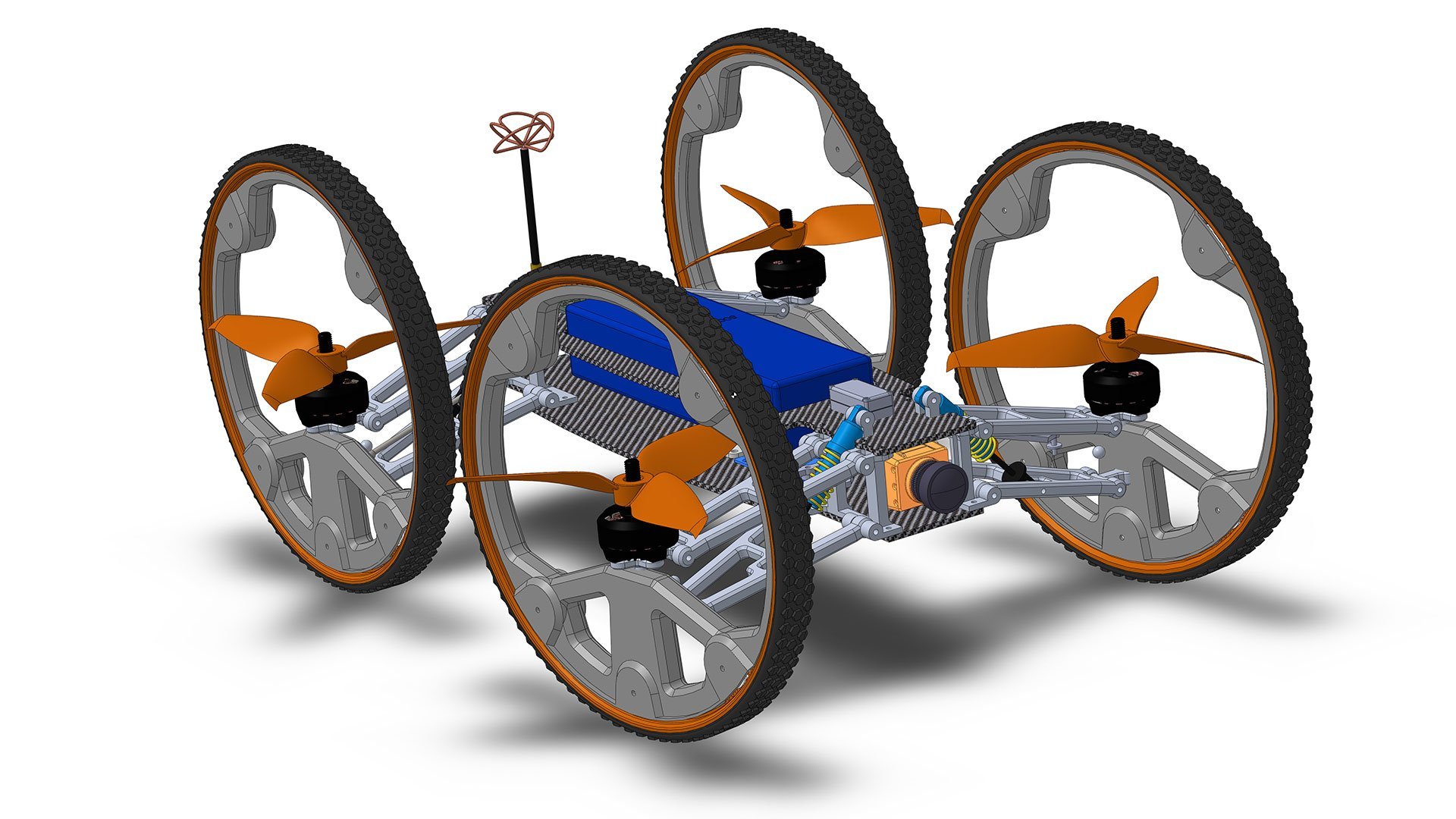

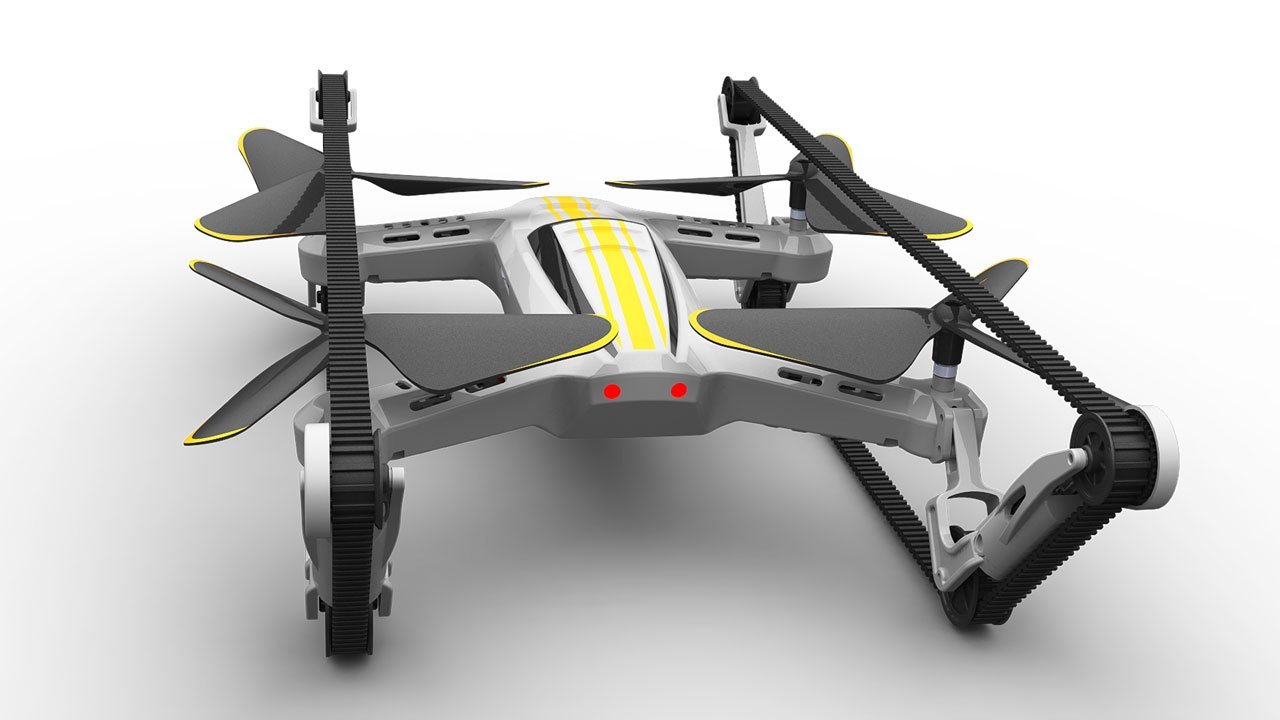

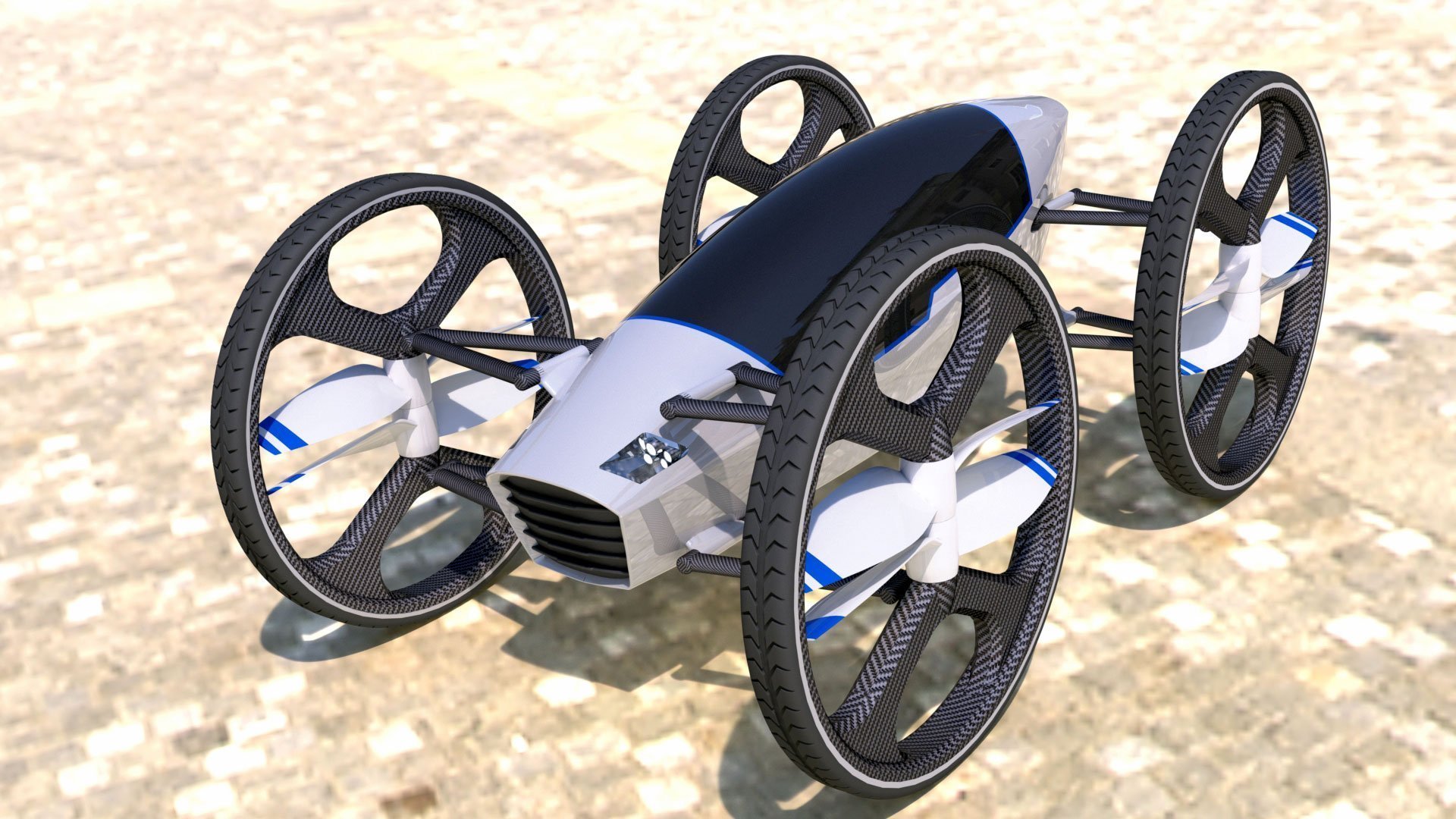

THE CARCOPTER DRONE CONCEPT 2

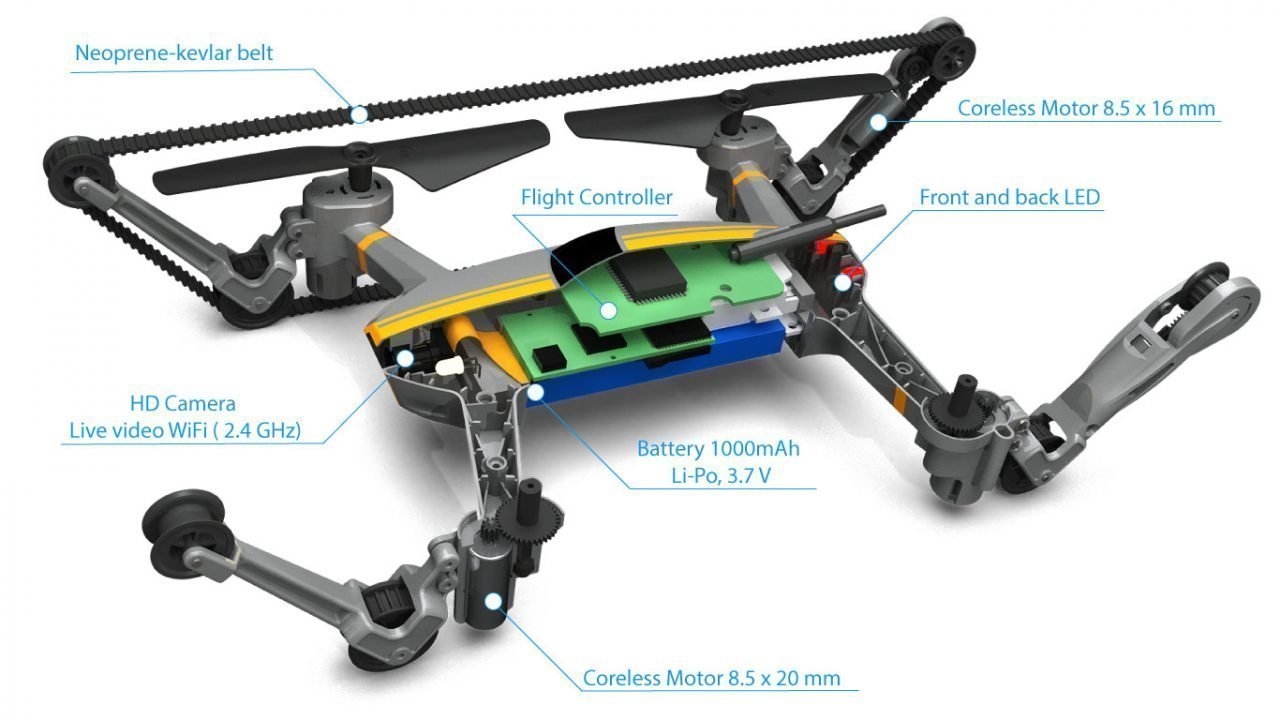

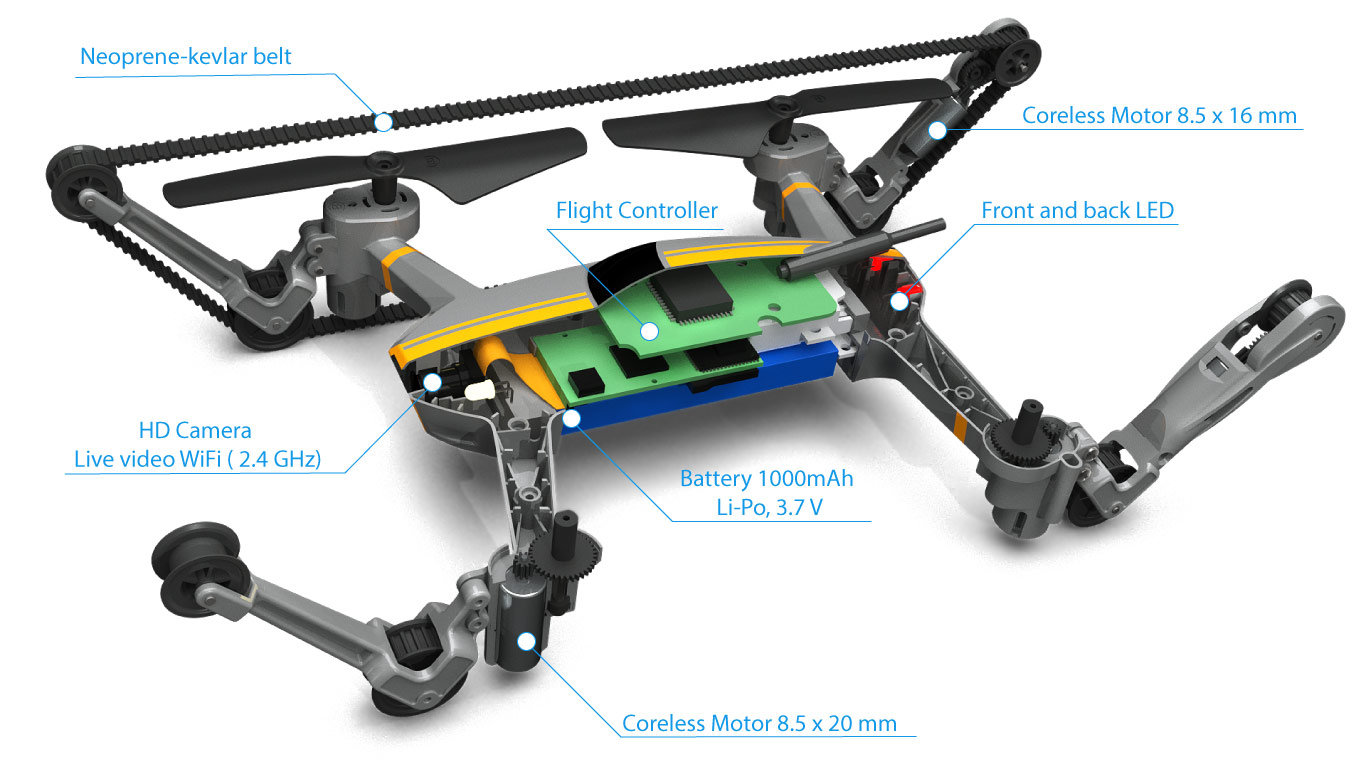

I would like to share with you an awesome news regarding the R&D of CarCopter drone

This is quite big and important update.

Once I got back to designing the second version of CarCopter, I had questions rising in my head. is is the first attempt to make such a drone, so I had no data to support my thoughts.

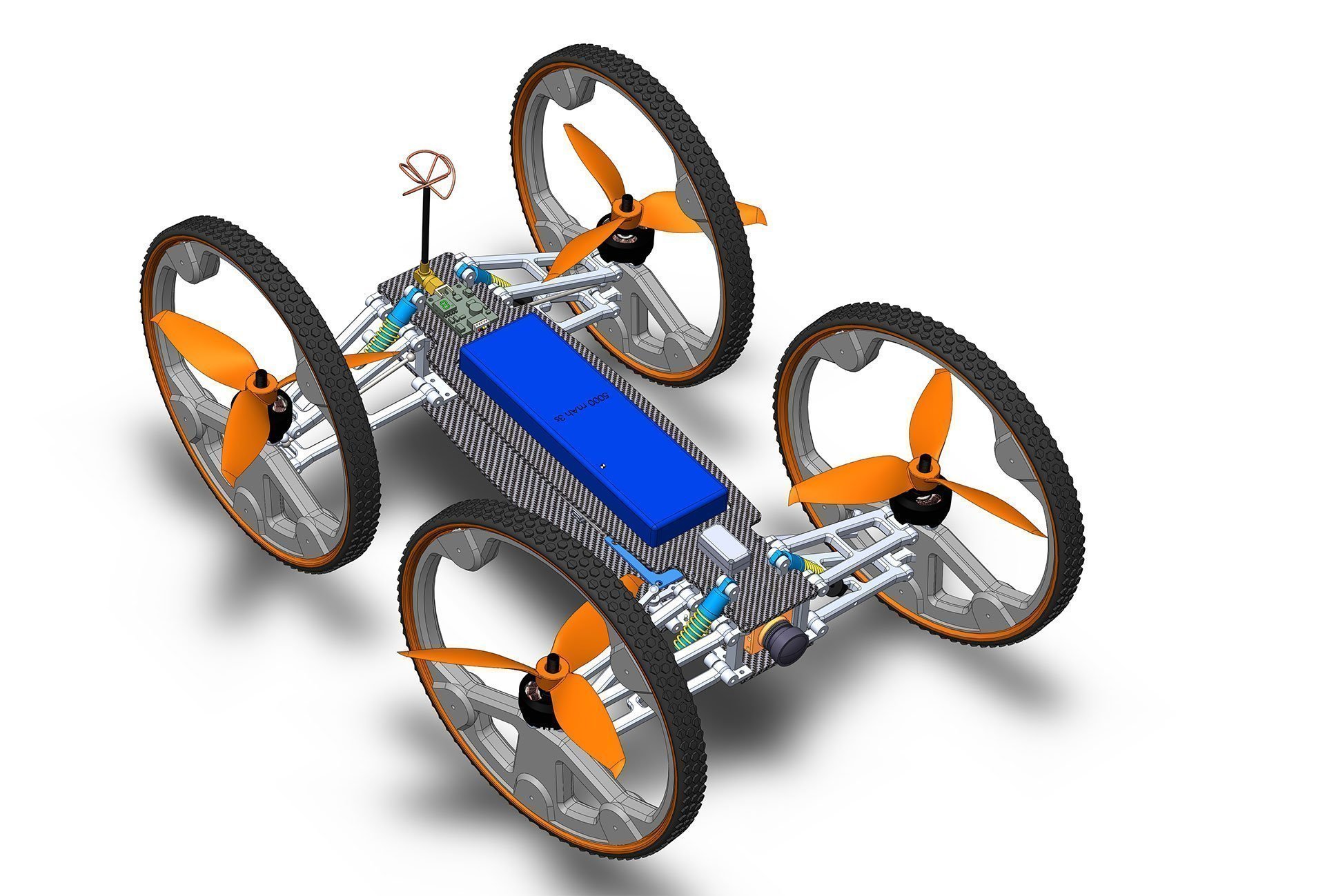

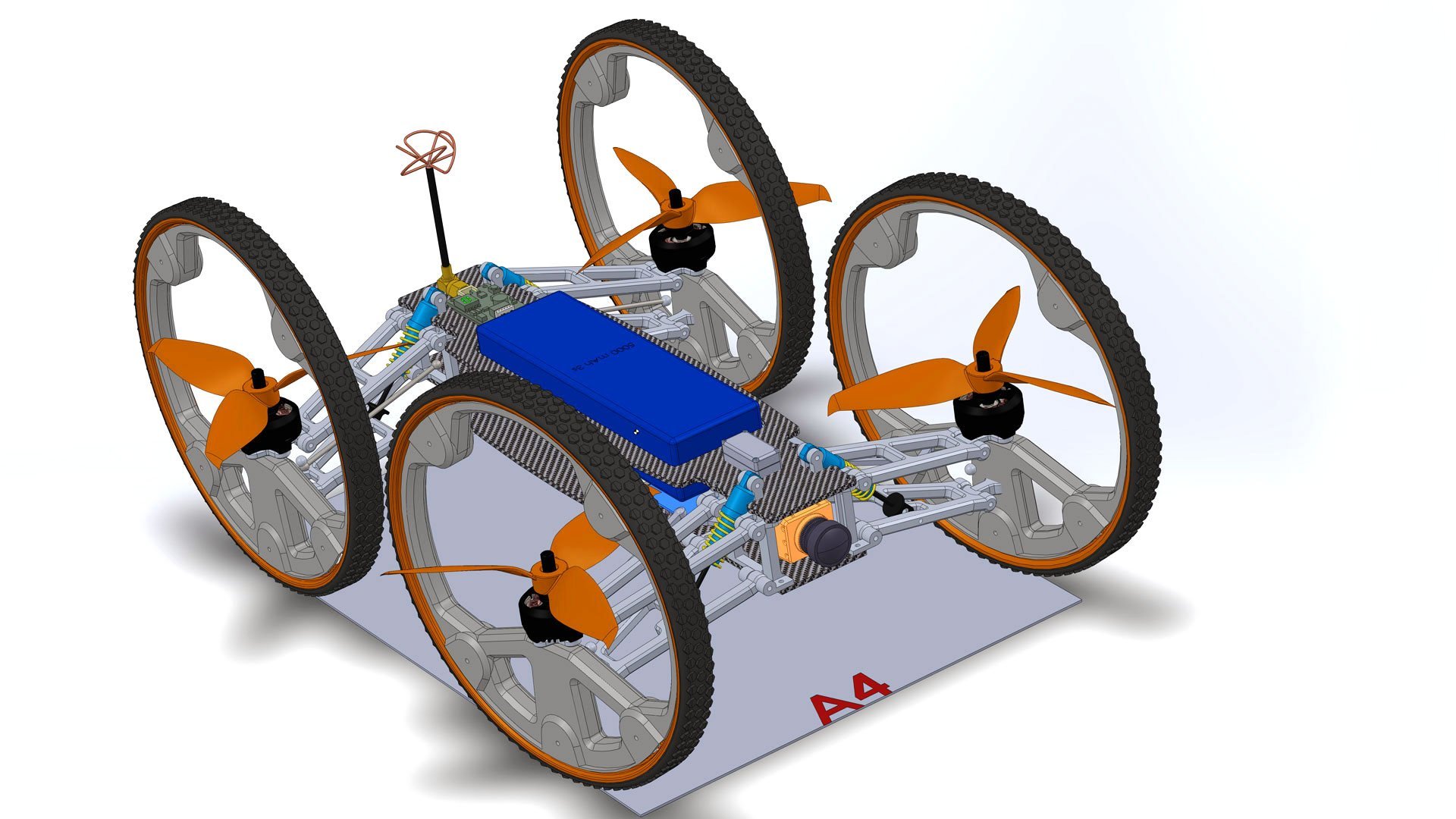

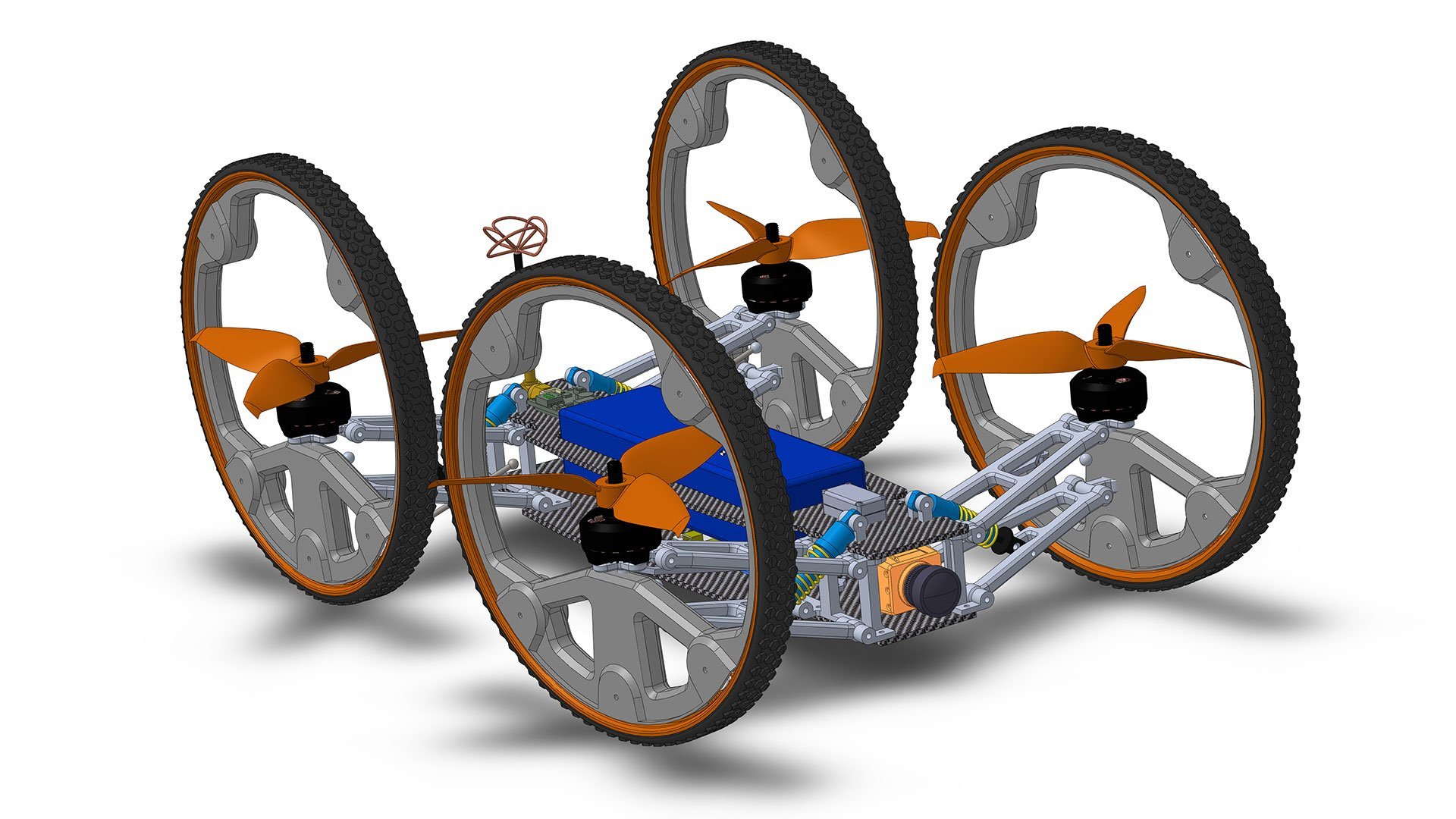

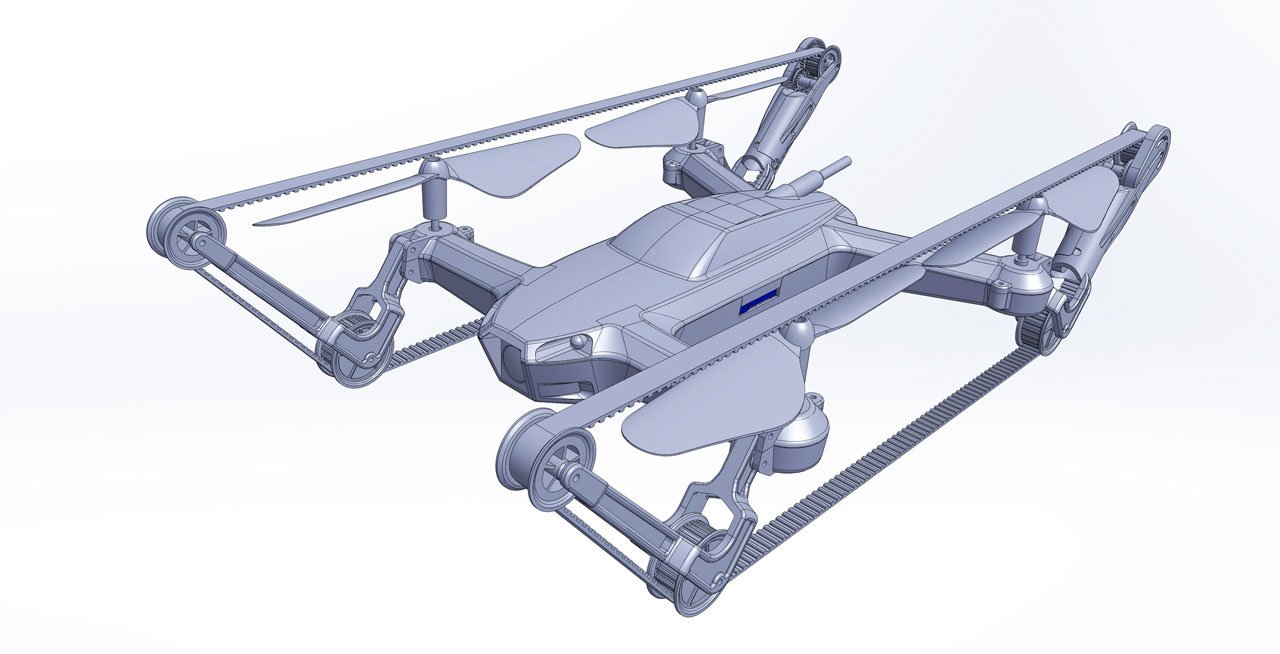

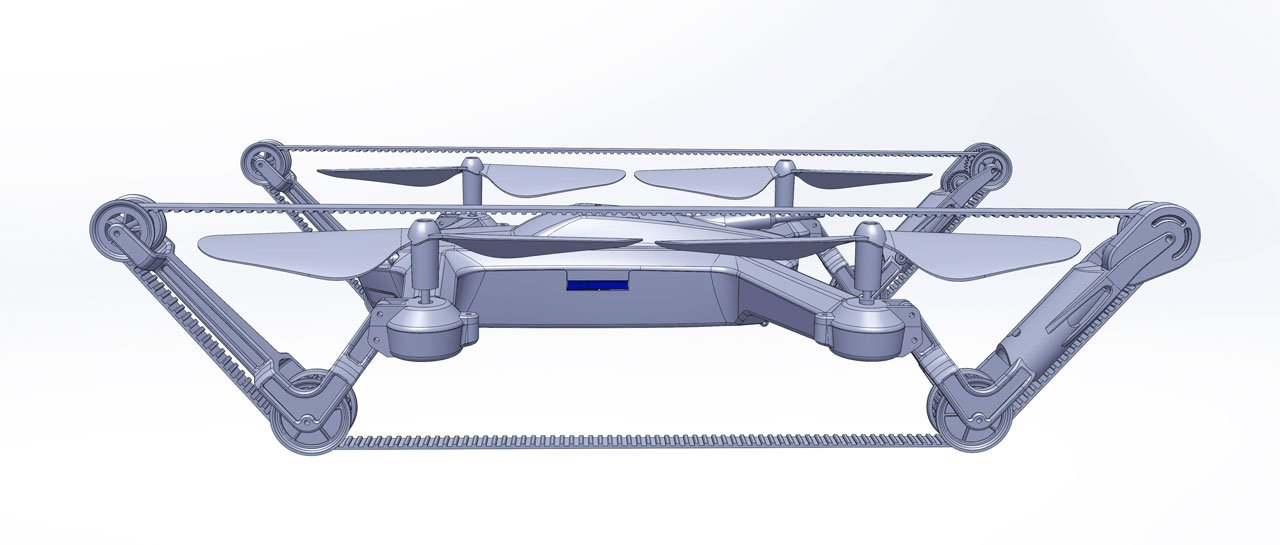

My big concern was if the quadcopter can fly with movable arms, equipped with suspension ( shock absorber, swaybar etc). Most of the engineers and people from RC world, which I asked for an opinion, told me straight away, that it will not be able to fly at all, as it is impossible to tune PID or software in such a way it will take into consideration the stroke of the arm ( suspension), its inertia, spring tension etc.. Saying shortly the system dynamic will be really bad for the drone flying.

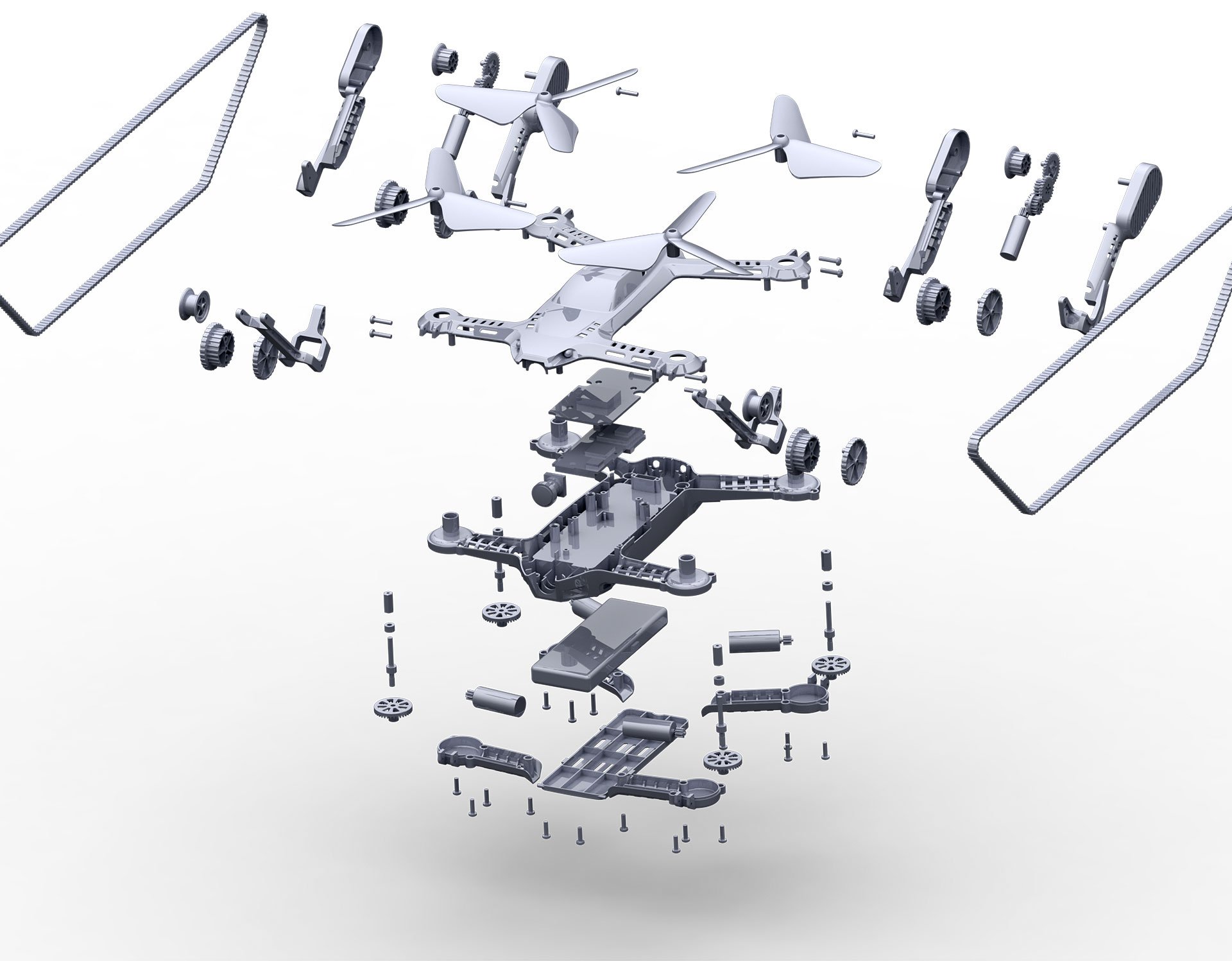

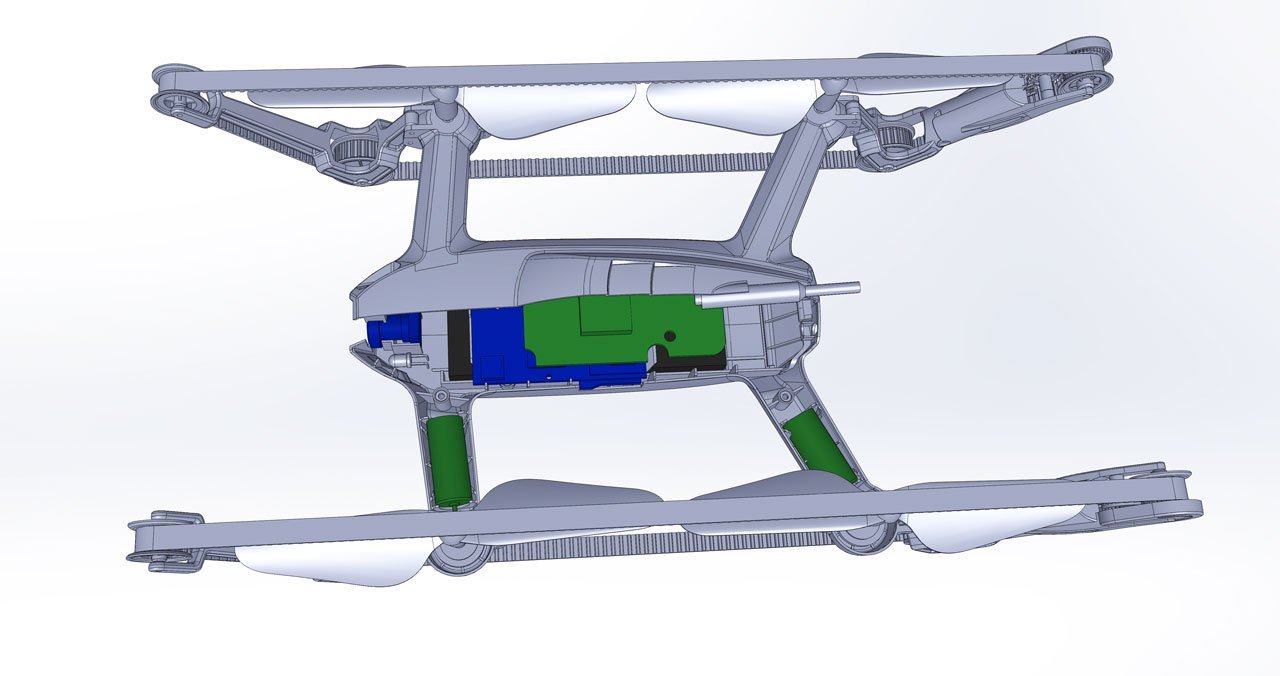

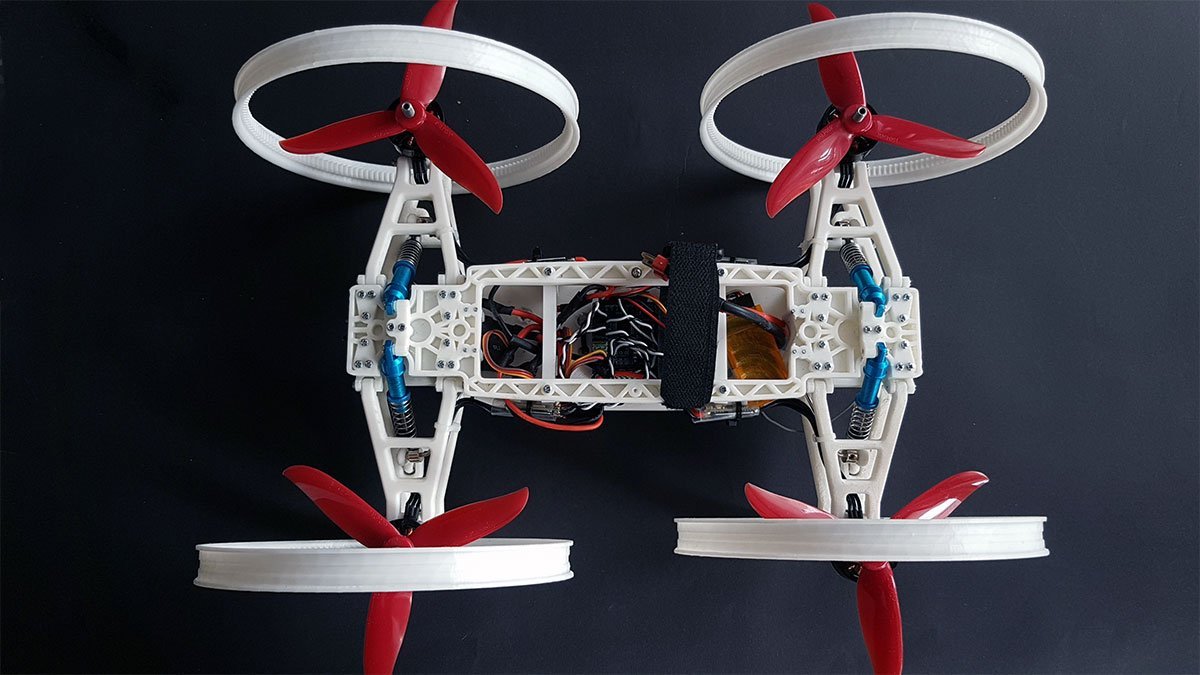

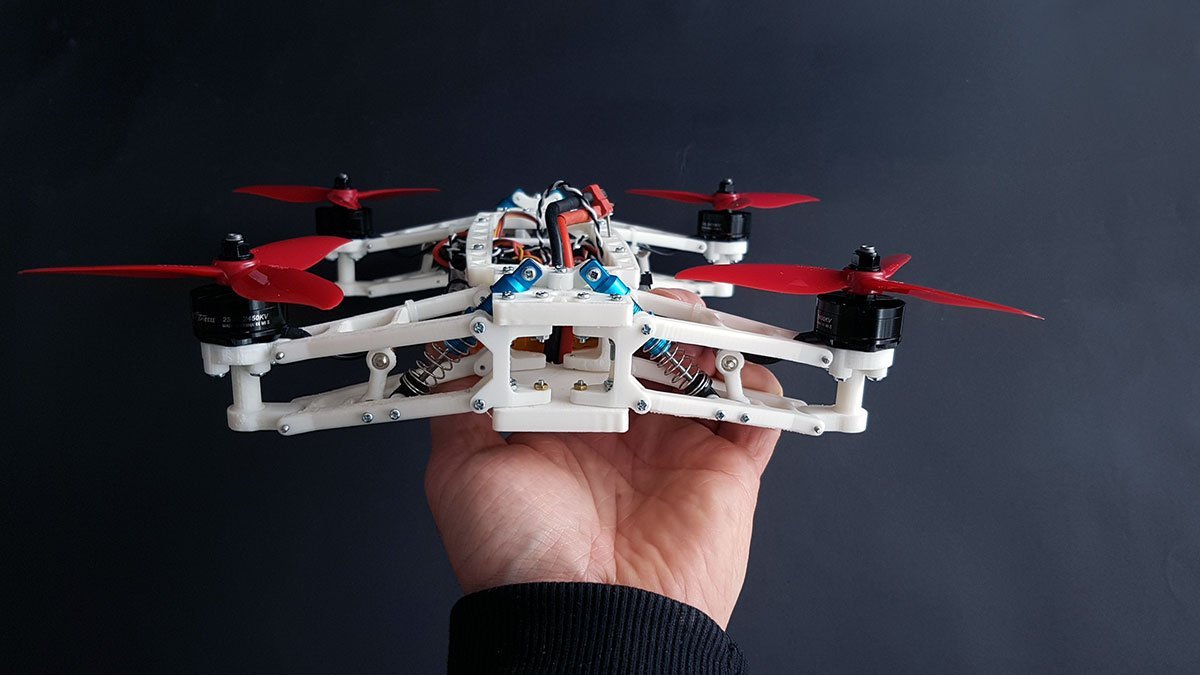

So thought, the problem can be easily solved by, designing the shock absorbers that can lock before the drone takes off. I started designing such shock absorbers, but midway I discovered many issues with this idea. So I decided to build a rough prototype to find out myself if the drone will actually fly.

To my surprise, the drone flies very well ! the arms can freely move up or down ( but the force vector does not change its direction, as all propellers despite moving up and down stay parallel to each other). It actually looks very cool once the drone is airborne and you can see suspension working.

I also noticed that arms absorb vibrations from motors, propellers and the drone seems to be more stable than with regular stiff frame.

Another thing that got my attention is the fact, that drone became more resistant ( it does not have to constantly adjust its position ) to lateral gusts. I think this is because arms absorb the gust force before it has the impact on the drone itself. (like in the car on the ground, the suspension is smoothening out bumps and vibrations, the same seems to be happening in the air). This finding obviously has a positive impact on the video quality.

I believe the drone is also more resistant to crashes, as the shocks can absorb a lot of impact forces before it gets transferred to the frame. ( you can see heavy RC cars being dropped from 3-5m hights, wiht no dmamages) . I have not tested yet the drone, I just assume that.

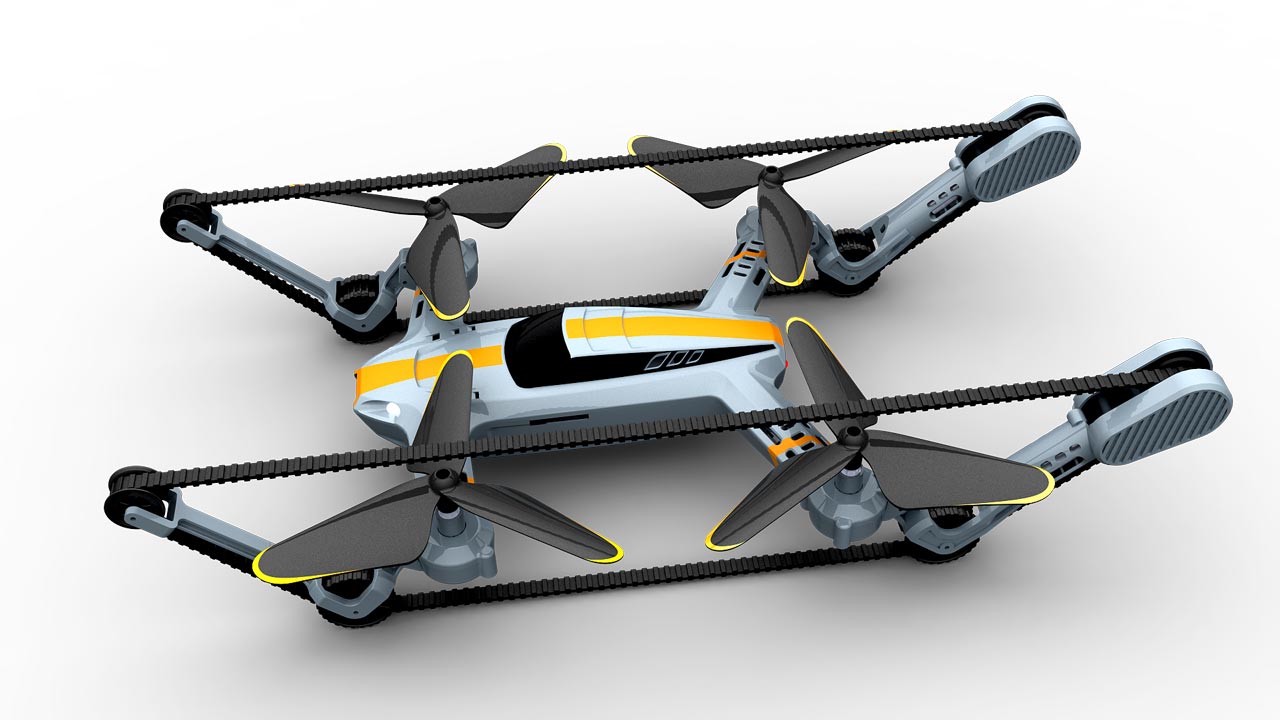

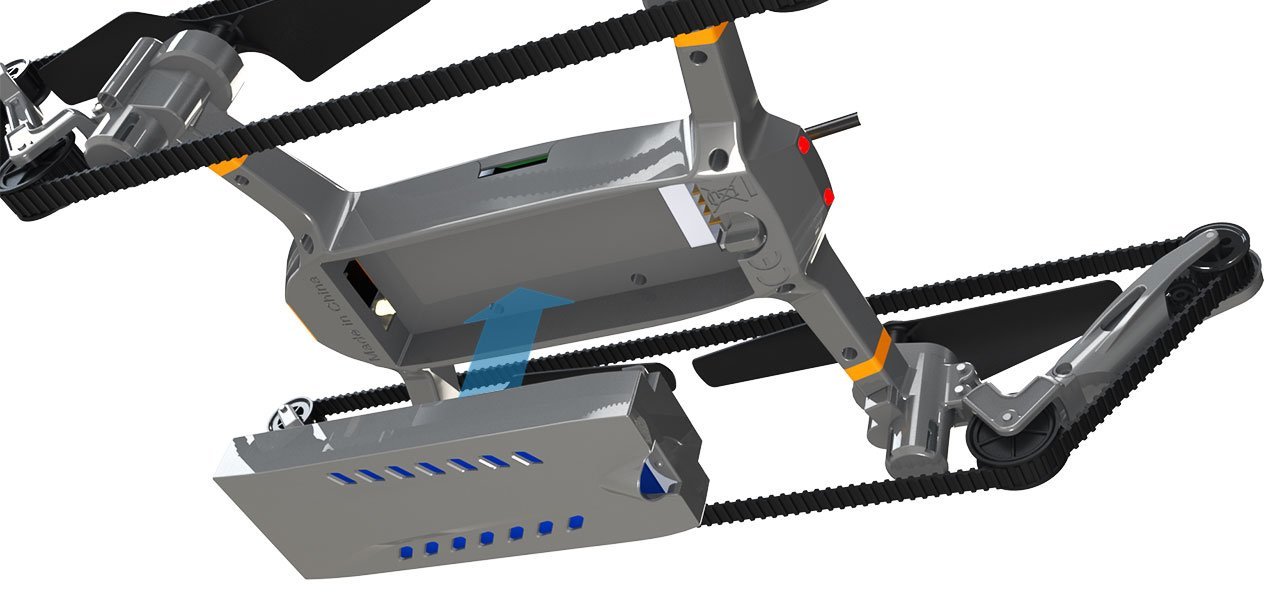

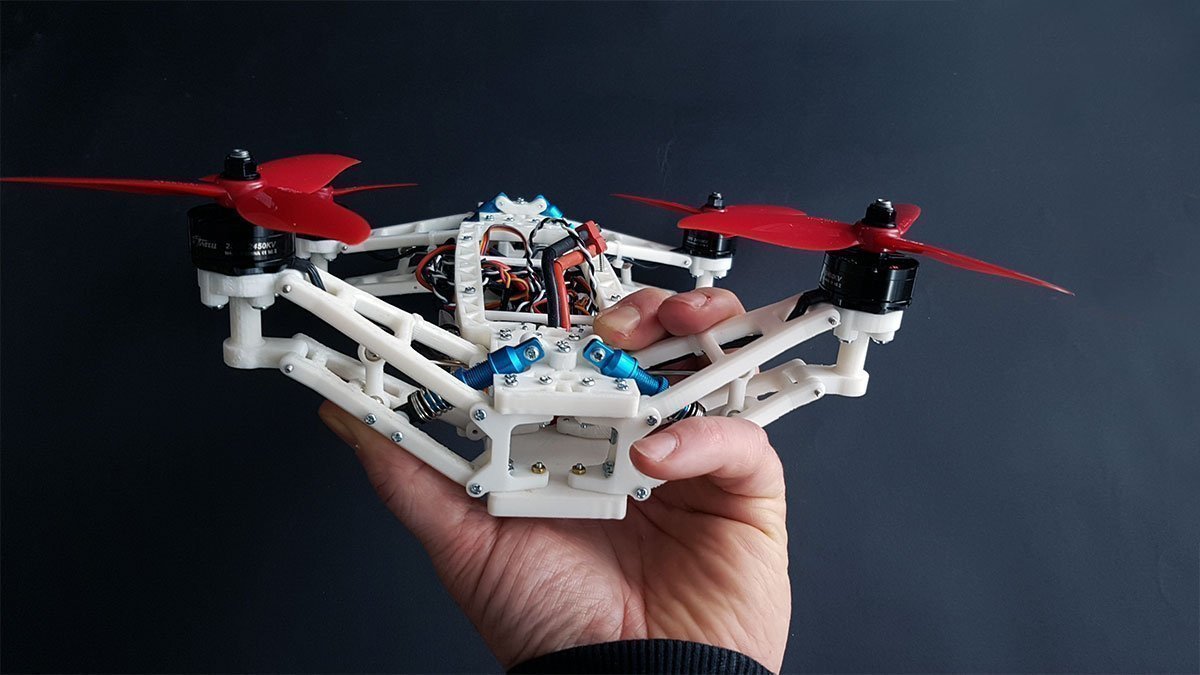

Apart from those findings, the most important for this project is the speed and ease of transition between drive and flight mode.

If I had to go down with the lockable shock absorbers idea, it would make the drone more complex, more expensive, heavier. The most important, the transition would be longer as the drone would have to stop, lock the arms and then take off, the same steps would be essential to the landing.

By having the suspension engaged all the time ( on the ground and in the air), makes things much simpler, cheaper etc. But the most important; it makes the fly/drive transition just awesome! As the drone will be able to literally droop down ( even from 1-2m height) straight on the wheels and drive.

Those finding + 16 cm in diameter wheels, 6 cm clearance !! 5.5 cm suspension stroke, the endurance of 12 min in the air, 20 min on the ground are really making the CarCopter idea really solid.

BTW: I will make a short video and share with you in next 2-3 days. SO stay around to see something very unique.

I know you have been waiting for so long for the model ( me too), and all you are amazing backers! That means a lot to me, thanks to you the project continues, and it is already in the last stage. I would like to give something in return for your patience. I will just wait for the factory to confirm the final pricing and I will update you what it will be.

I know you have been waiting for so long for the model ( me too), and all you are amazing backers! That means a lot to me, thanks to you the project continues, and it is already in the last stage. I would like to give something in return for your patience. I will just wait for the factory to confirm the final pricing and I will update you what it will be.